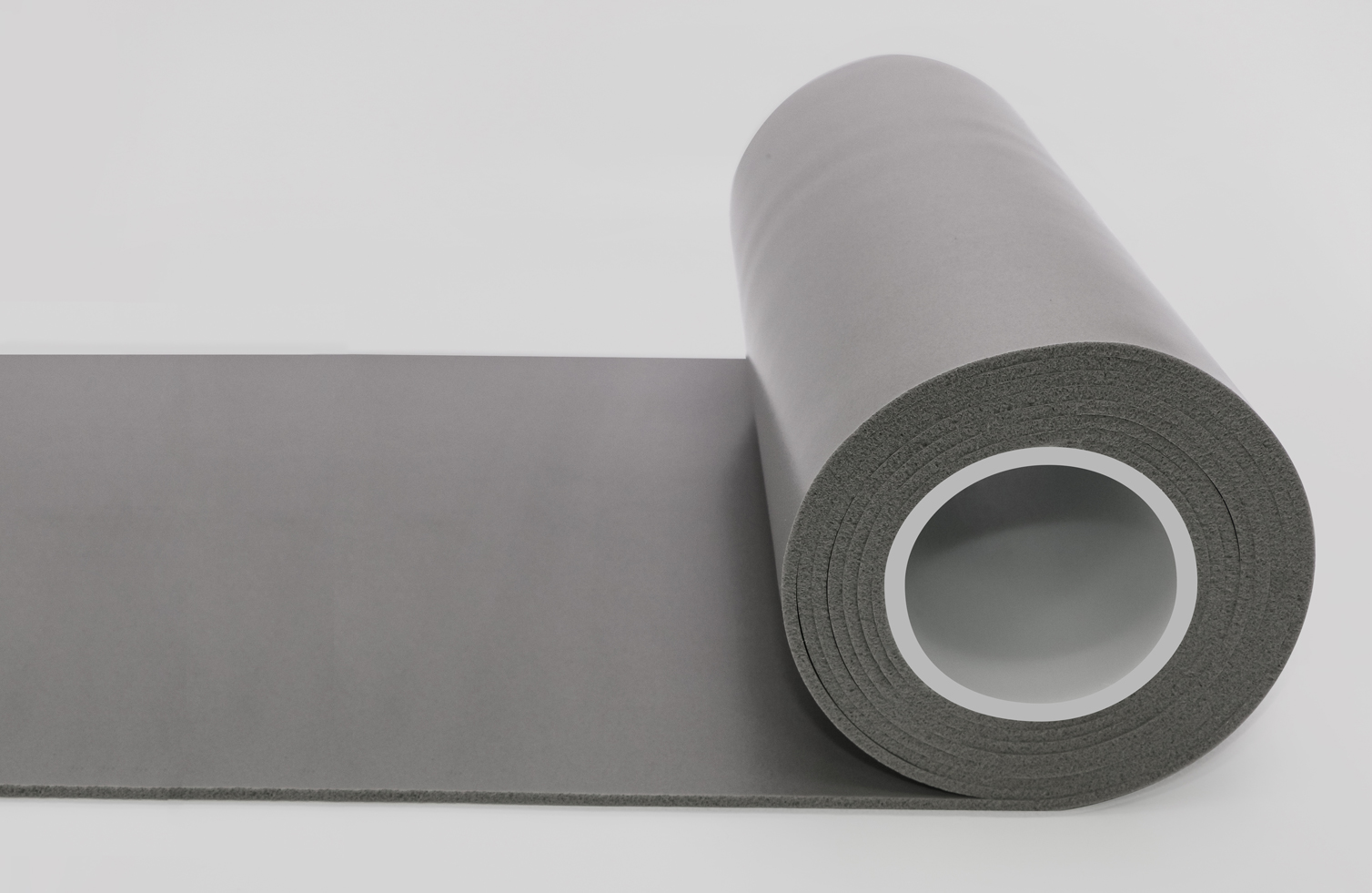

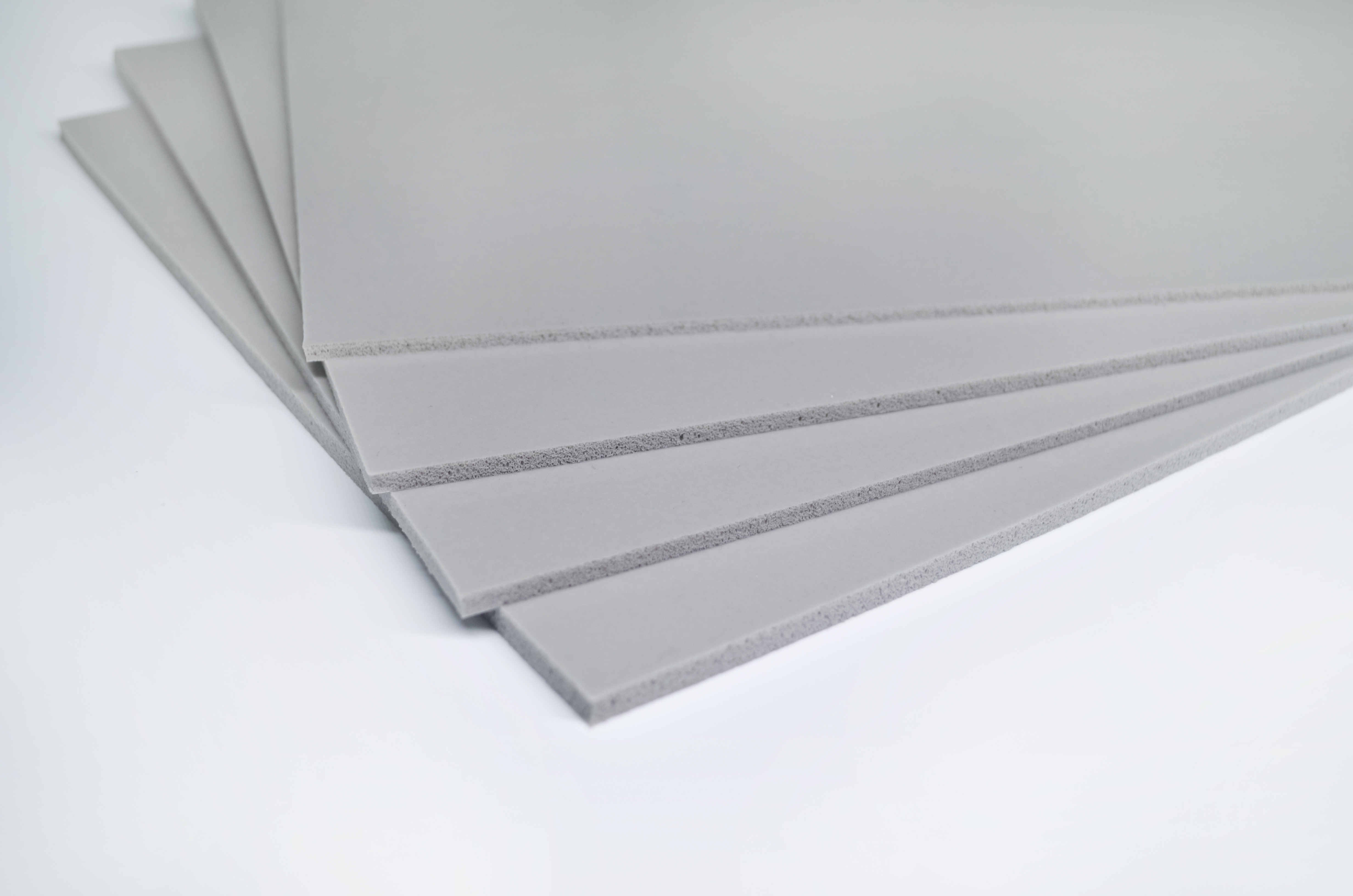

FUTUREWAY® Silicone Foams have the characteristics of high elasticity, compression resistance, creep resistance, flame resistance and fireproof. It is suitable for sealing, shock absorption, cushioning, thermal insulation and other applications, and meets electric vehicles, energy storage, photovoltaic, industry, consumer electronics and other industry requirements.

Resilient Compression

Maintains high elasticity and stress levels, reducing replacement frequency.

Broad Compression Stress Range

High compressibility ensures load-bearing within required limits for greater compression range, accommodating diverse design specifications.

Unparalleled Weather Resistance

Resistant to UV, ozone, and extreme temperatures, and stable performance in various complex environments.

Wide Operating Temperature Range

Long-term usability within a temperature range of -55℃ to +200℃

Flame Retardant

Meets UL 94 V-0 flame resistance requirements.