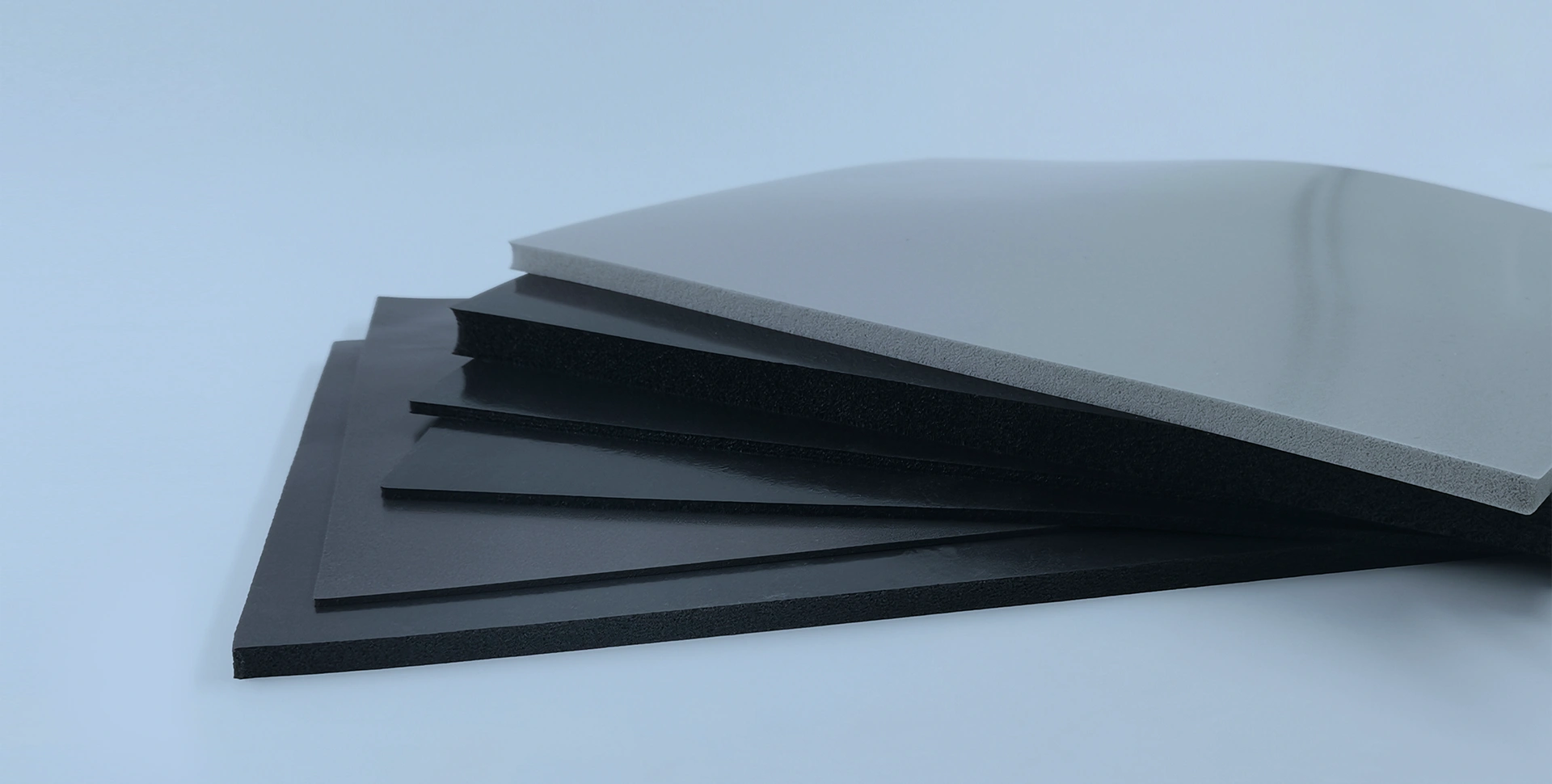

FUTUREWAY® Low Smoke Silicone Foams are high elasticity silicone foam with excellent flame resistance, friendly combustion behavior, high and low temperature resistance, ozone resistance, radiation resistance, and super compression deformation resistance.

Unparalleled Weather Resistance

Resistant to UV, ozone, and extreme temperatures, and stable performance in various complex environments.

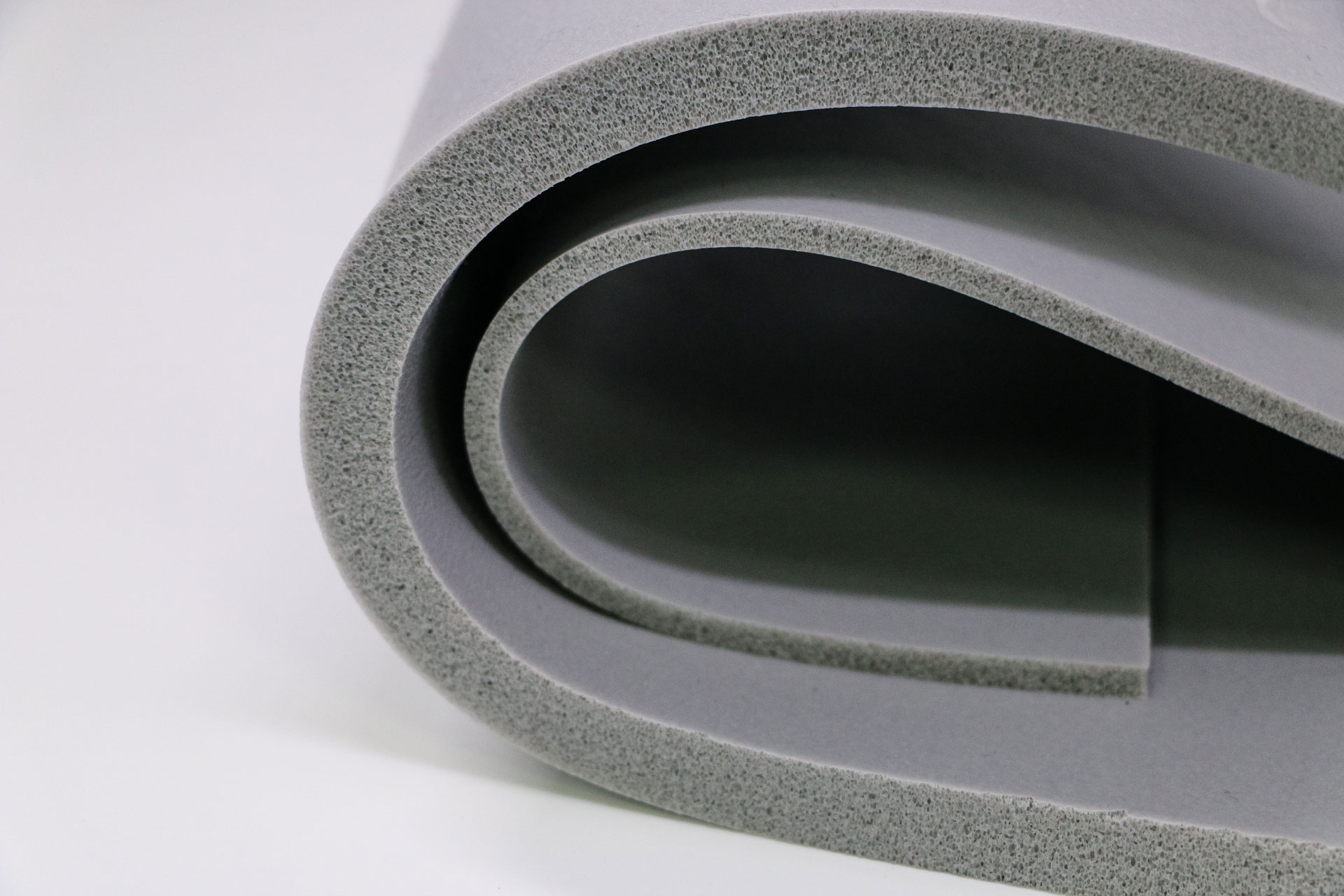

Compression Resistance

Maintains a low permanent compression set in high-temperature environments.

Flame Retardant

Meets UL 94 V-0 flame resistance requirements.