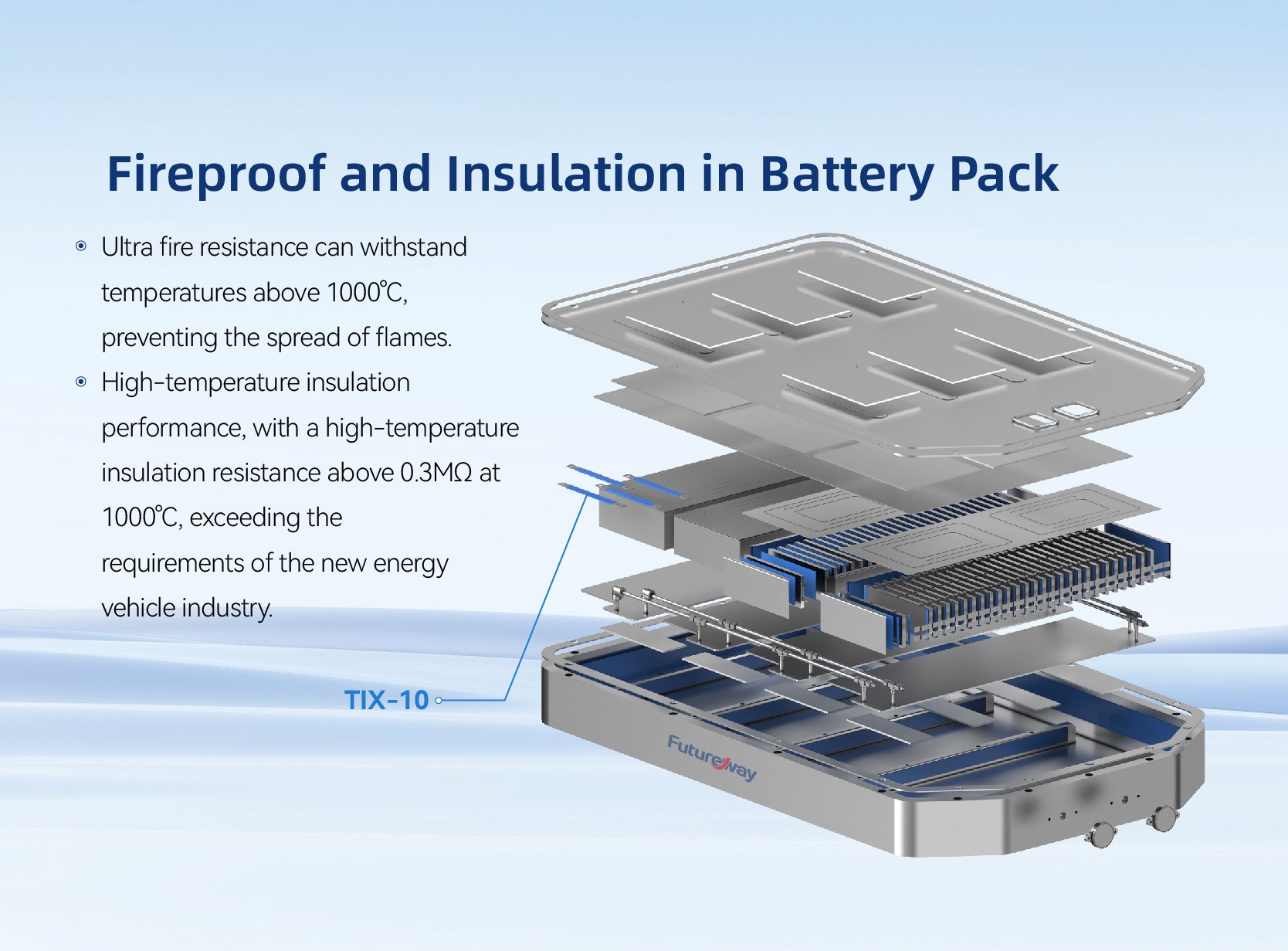

Fireproof and Insulation Application in Battery Pack

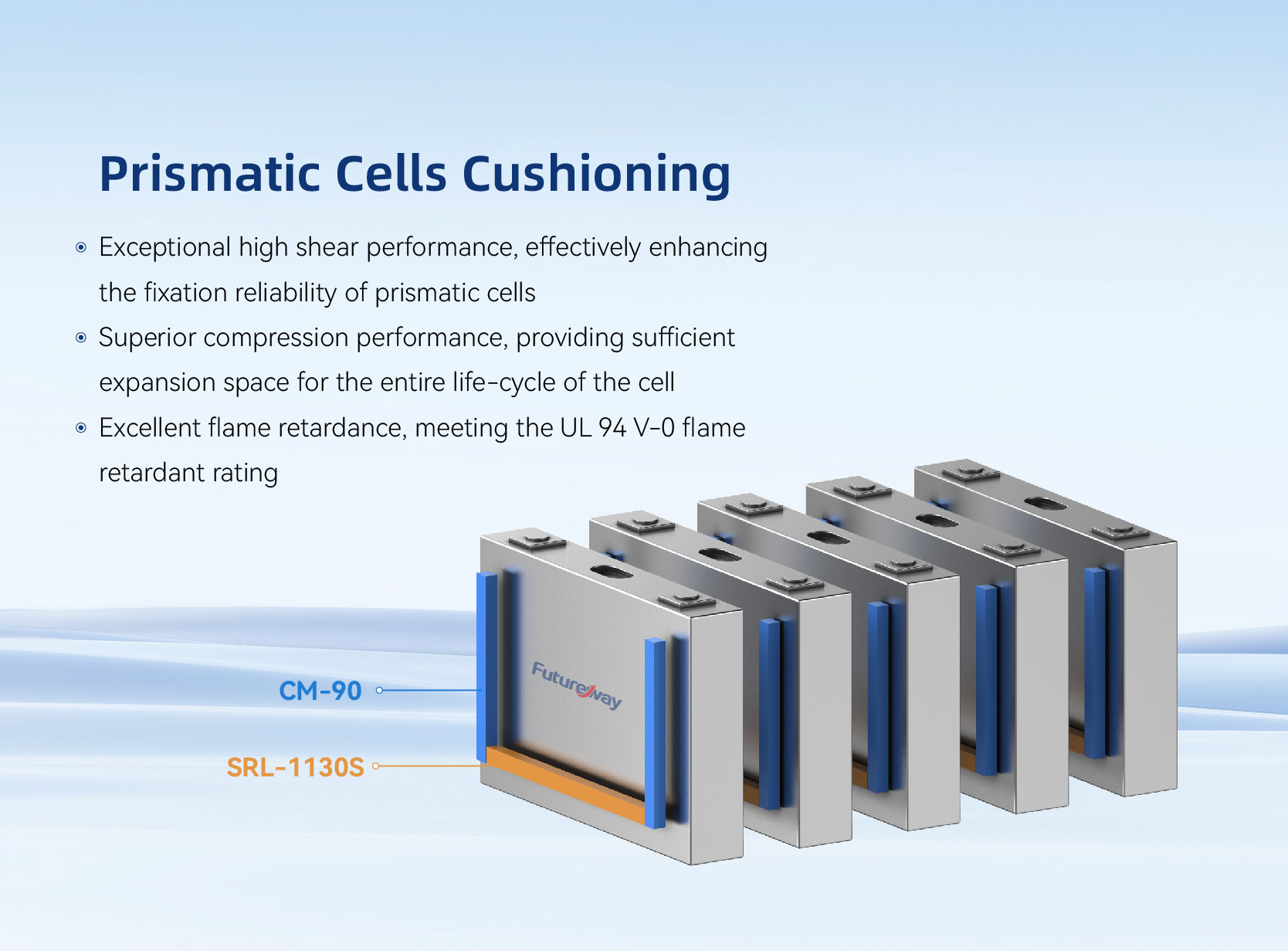

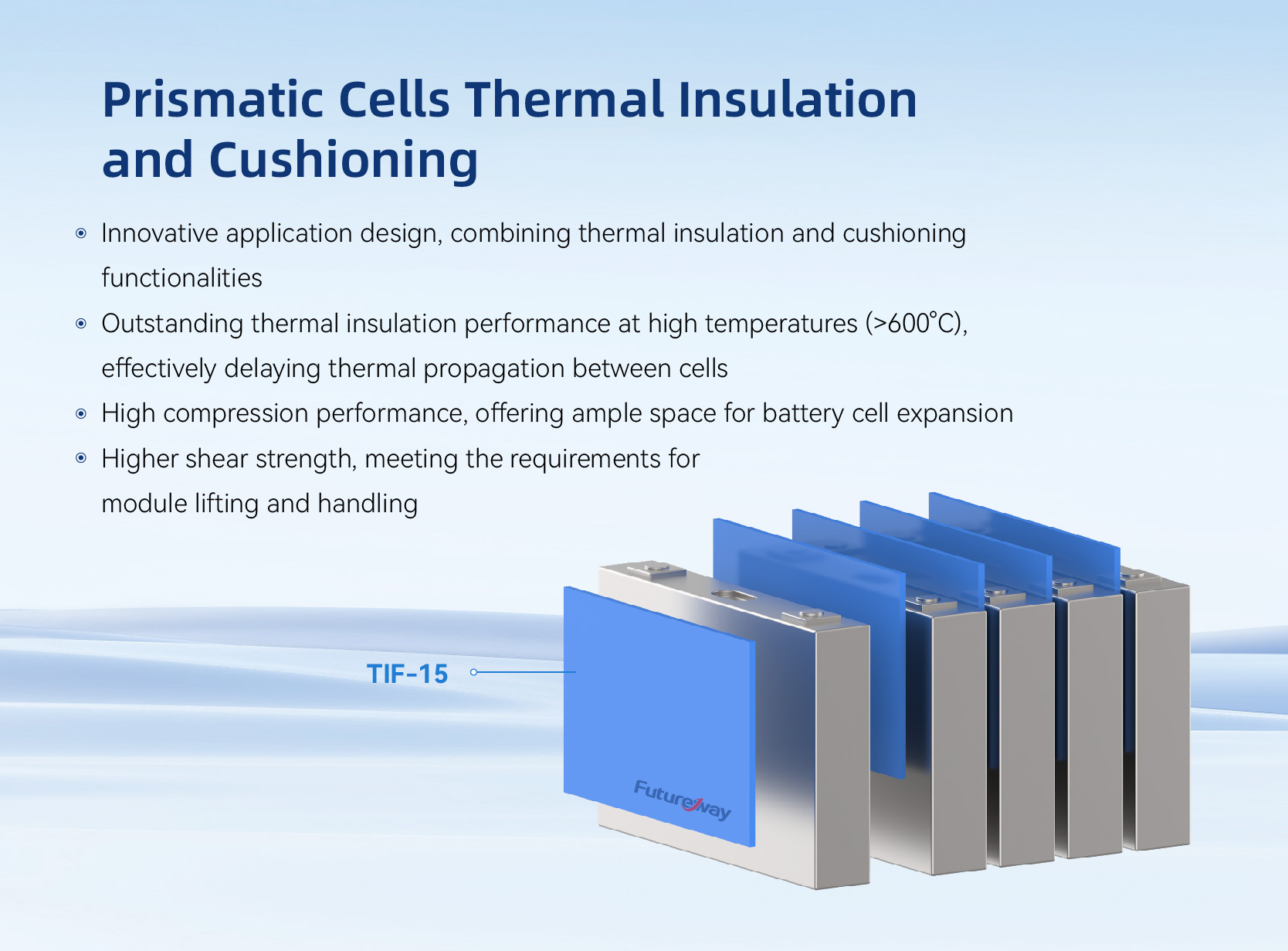

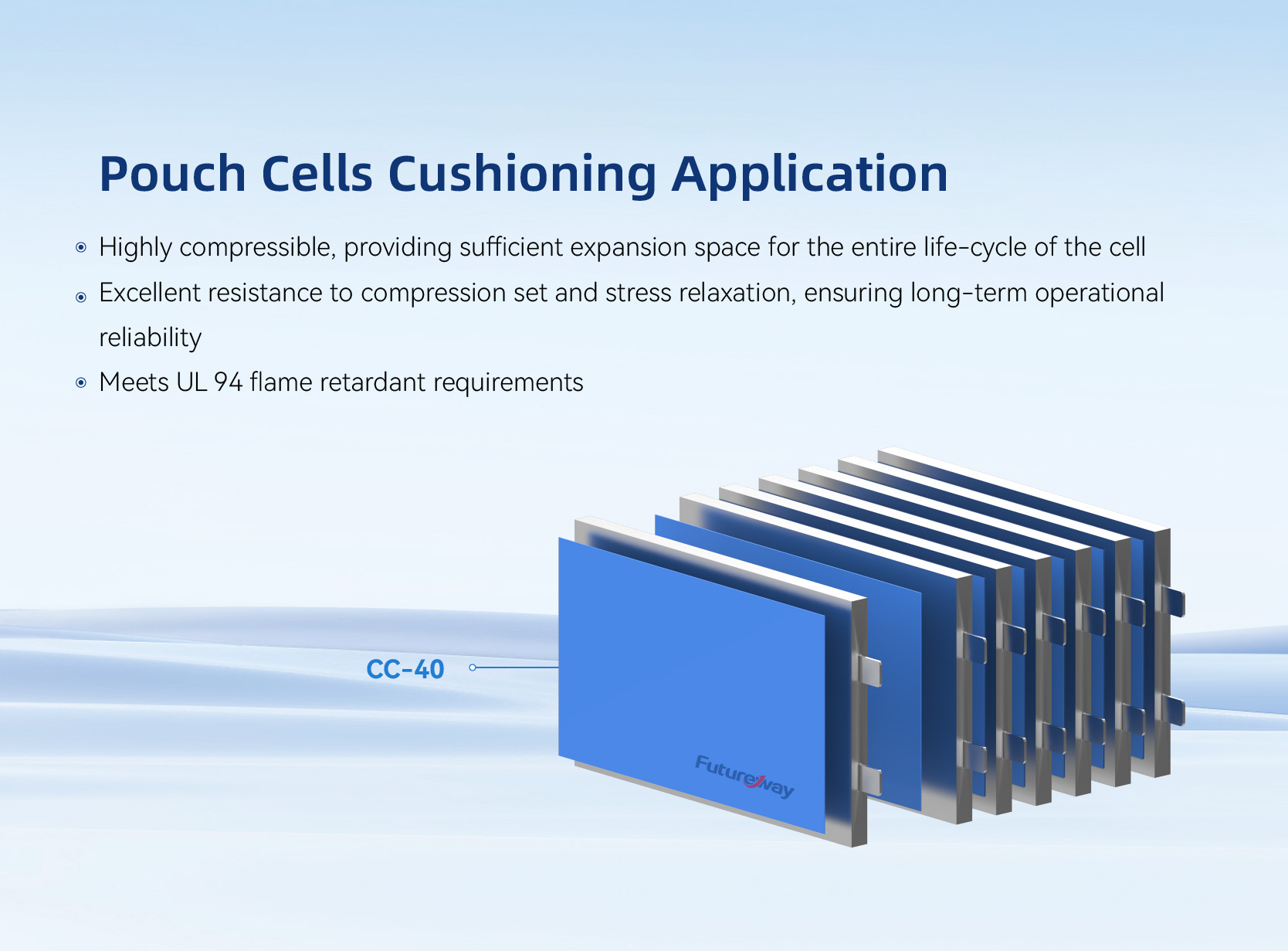

When the battery pack gets out of thermal control and short-circuits occur, it may lead to fire, which seriously threatens the lives and properties of passengers. Therefore, the selection of fireproof insulation materials is of great significance to avoid the occurrence or spread of fire. In the selection of materials, the main consideration is fireproof and high temperature insulation performance, which can effectively isolate the fire source and inhibit the spread of fire. It is also necessary to reasonably arrange the fireproof material layer, not only to ensure a close fit to the electric core, but also not to affect the normal operation of the battery pack structure and other systems, such as refrigeration systems. Scientific fire insulation design plays an indispensable role in the safety system of new energy vehicles, providing effective protection for vehicle occupants and the surrounding environment in emergency situations.